Support software RCX-Studio 2020 Feature

Programming software for RCX 3 Series Controller

Feature

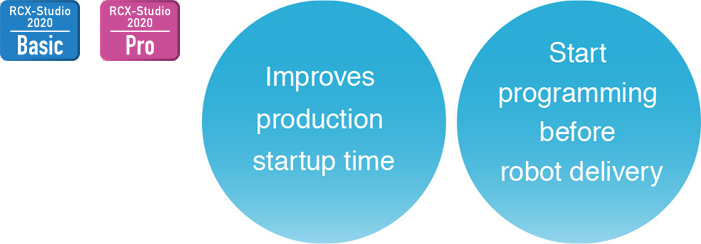

New features to greatly reduce startup time

RCX-Studio 2020

Programming software for RCX 3 series controllers.

New functions such as 3D simulator function and program template (program template automatic creation function) are added for ease of user operation.

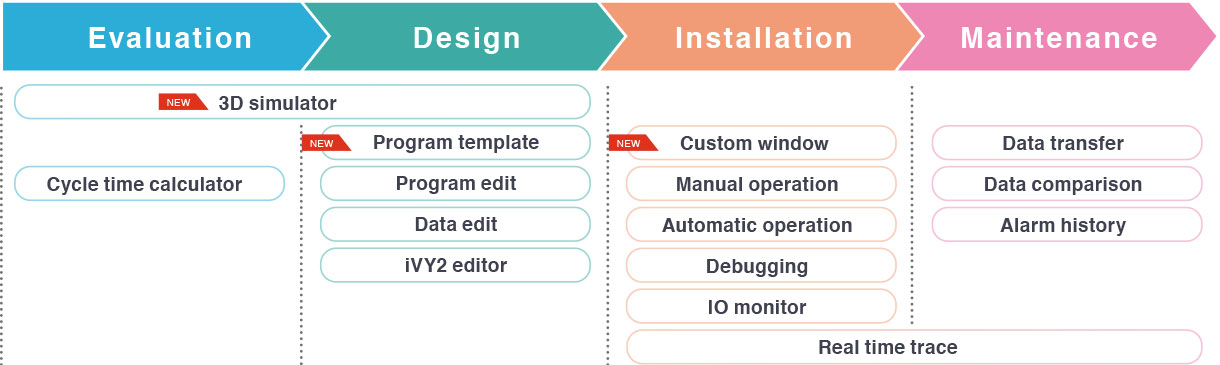

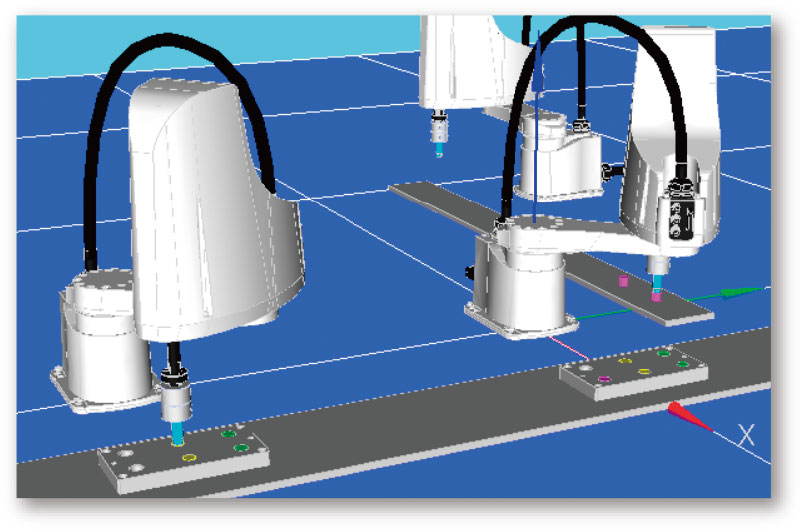

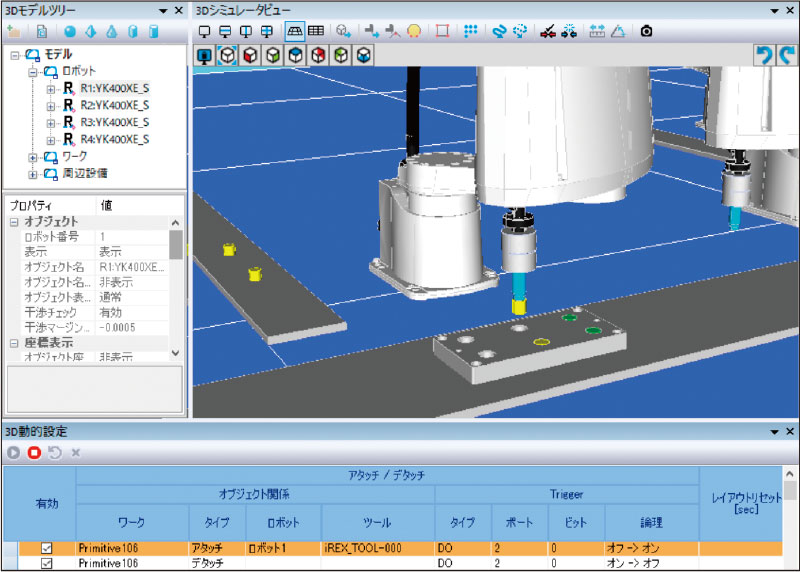

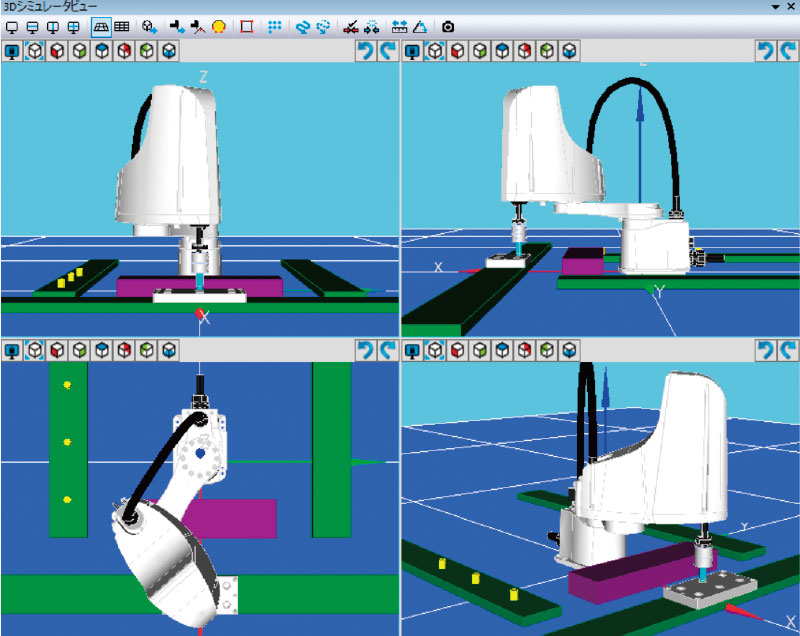

3D simulator NEW

Layout can be verified beforehand without connecting robot.

Robots and peripheral devices are displayed in 3D, and the robot operation is simulated on PC.

▶ Robot layout, teaching, and debugging can be performed.

▶ Physical interference between the robot and peripheral device can be checked before operation is started.

3D CAD Data imported

■ Multiple robots are supported (up to 4 robots).

*Only SCARA robot is supported. Cartesian robot and single-axis robot are not supported.

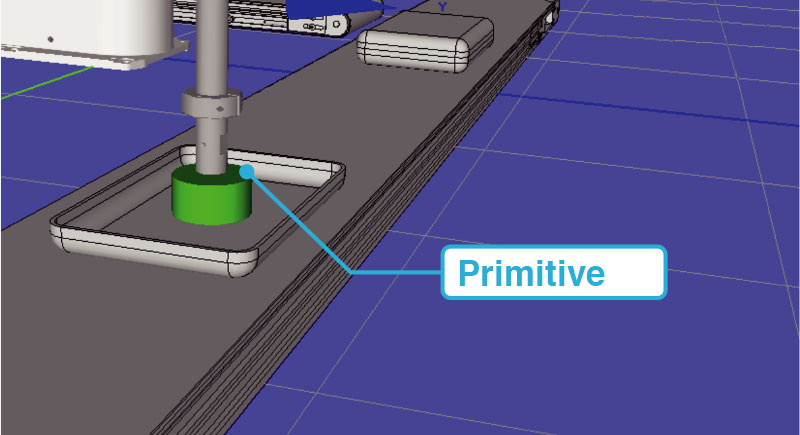

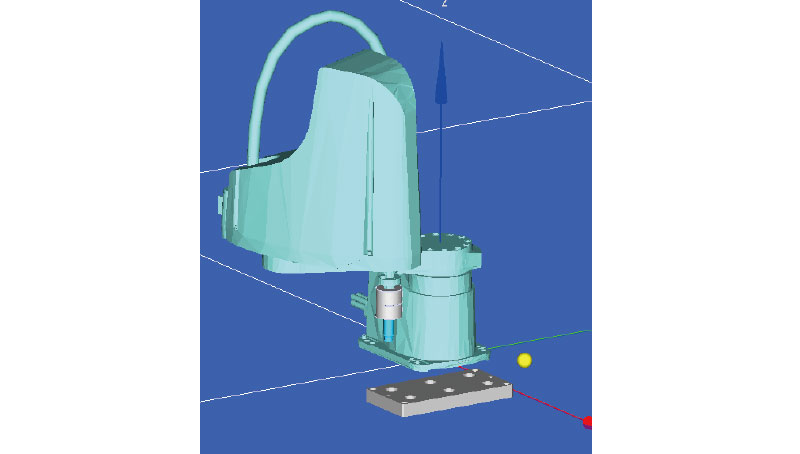

Peripheral devices are displayed using primitives

■ Peripheral devices and workpieces can be displayed using simple shapes (primitives).

Teaching virtual robot on screen

■ Teaching of the current position can be performed by moving virtual robots using the jog or mouse operation.

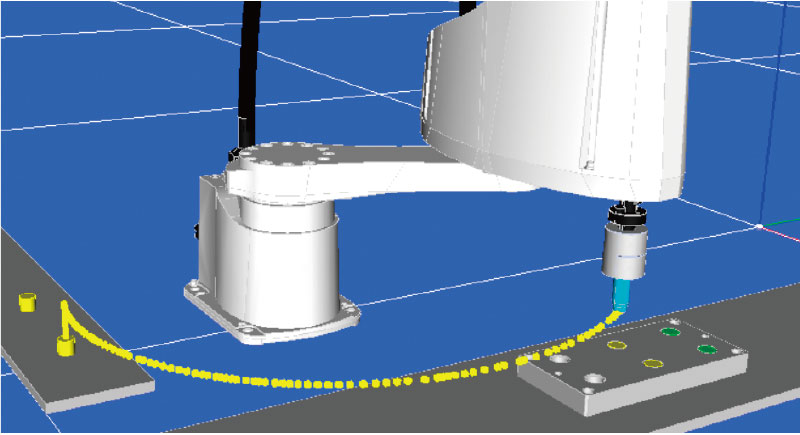

Operation area is verified by tracing the movement of end-of-arm effector and partsves

■ Visually tracing robot move

■ Movement of workpiece and end effector can be displayed.

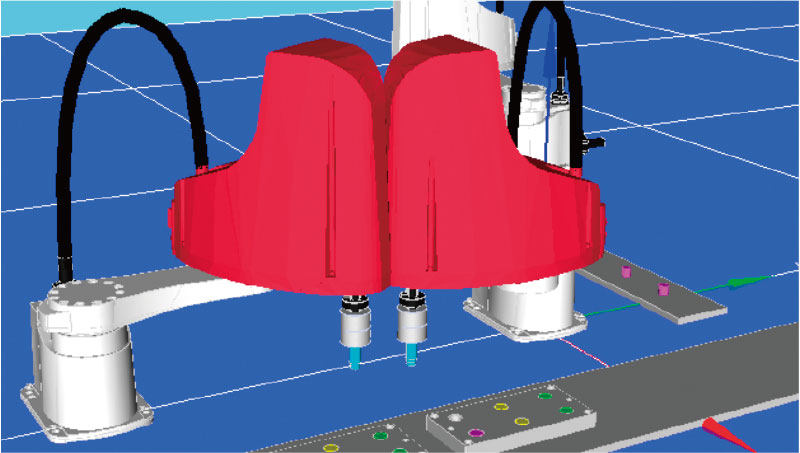

Interference with the production units is checked to avoid collision with other devices

■ Interference between the robot and peripheral device is checked.

*Interference check is performed at the screen drawing timing. Therefore, the interference may not be detected depending on the execution environment and operation status of the software. To perform the accurate check, it is recommended to decrease the operation speed of the robot and perform the check several times.

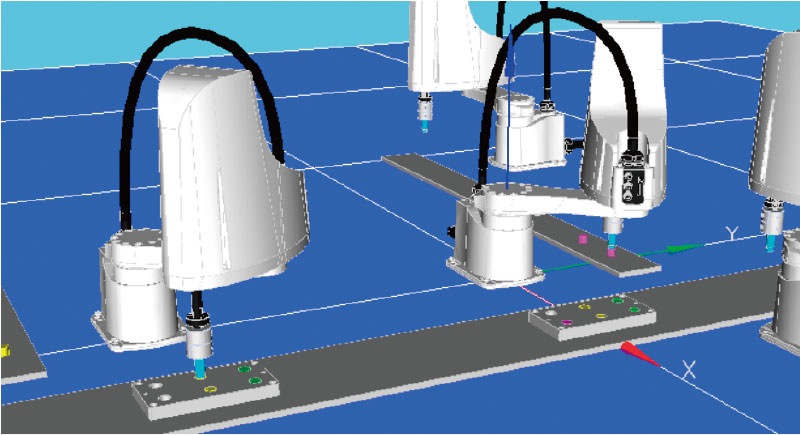

Multi-angle View (Screen division function)

■ Layout can be checked from multiple viewpoints at the same time

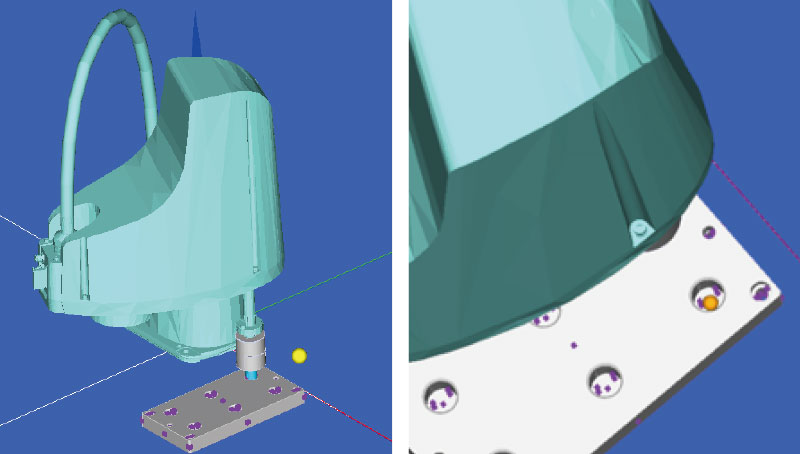

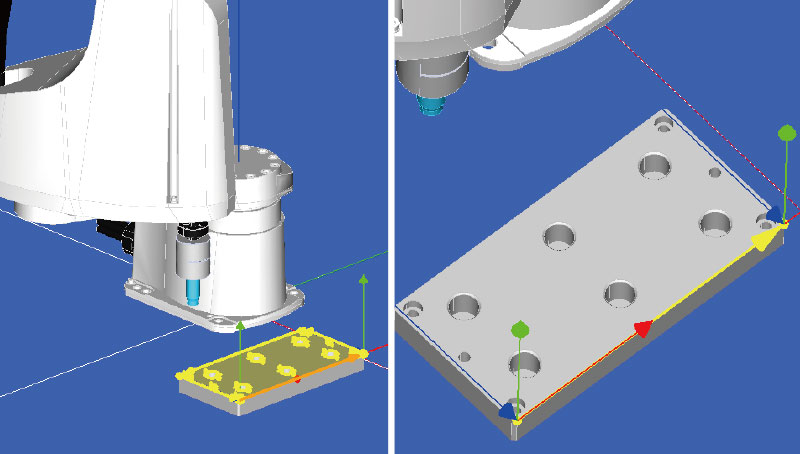

STEP data file can be imported

Characteristic points with STEP file data are displayed

For the STEP data, characteristic points of the 3D CAD data are displayed. Clicking the characteristic point moves the robot.

3D CAD Data feature points are not displayed

For data other than the STEP data, characteristic points of the 3D CAD data are not displayed.

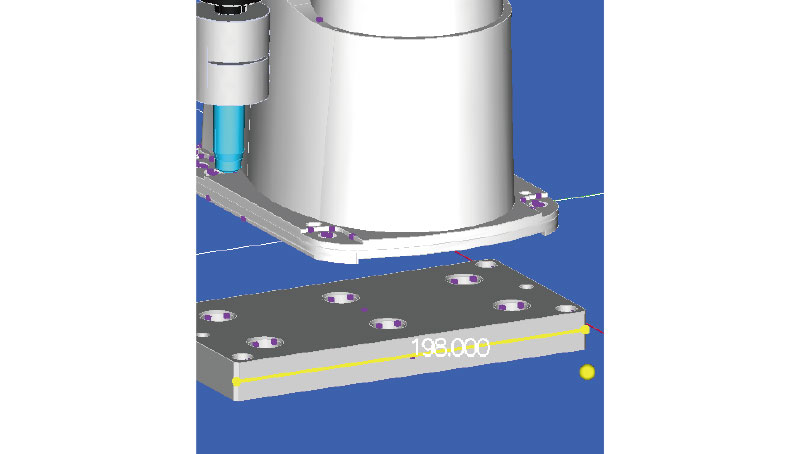

Measurement of distance and angle

With STEP file data the distance and angle can be measured using the characteristic points on the edge.

Creation of edge point data

With STEP file data the characteristic points on the edge can be converted into the point data.

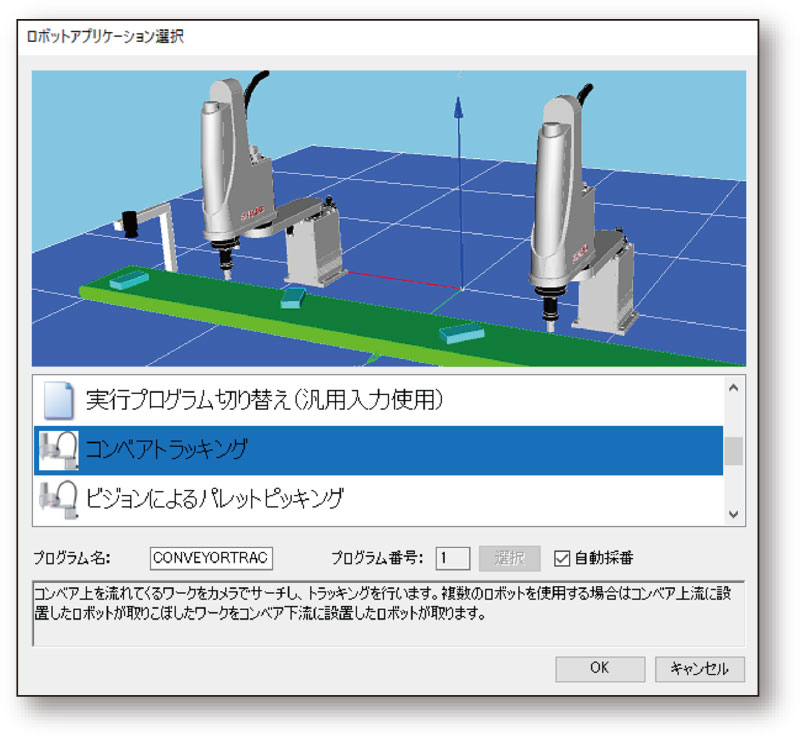

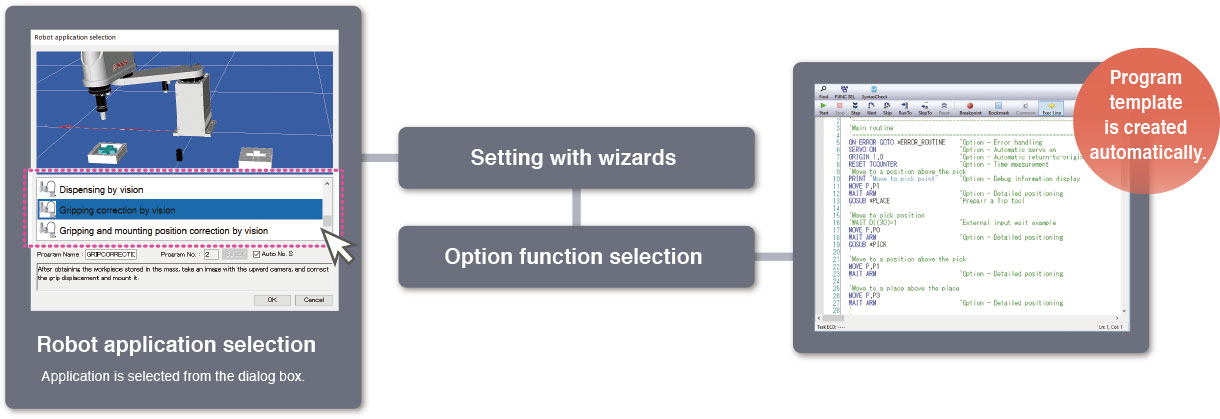

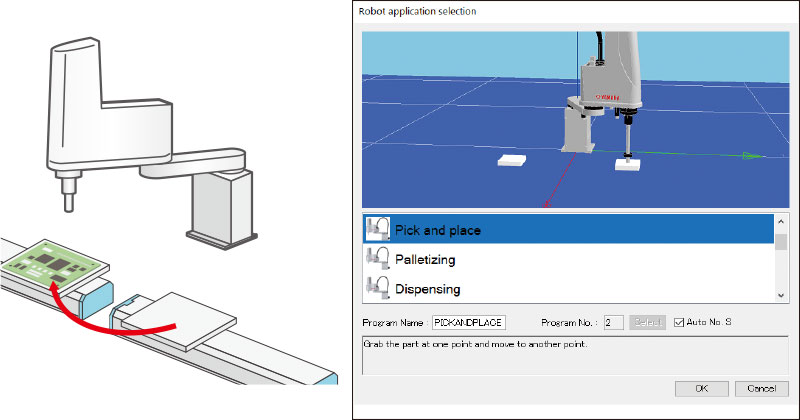

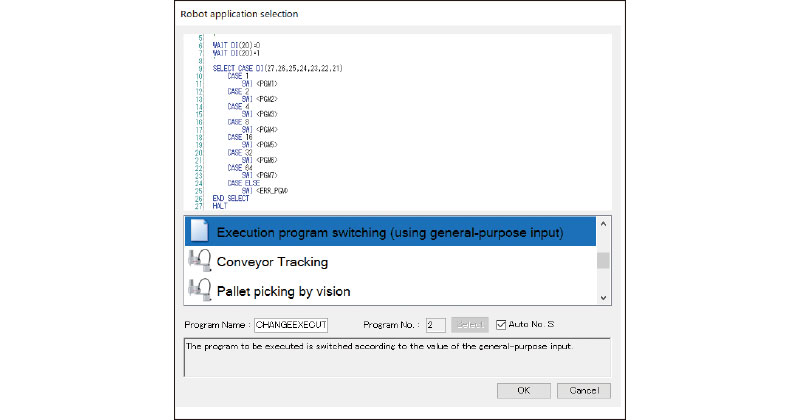

Program template (Program template automatic creation function) NEW

Program creation time can be shortened greatly.

Program templates for 10 types of applications are incorporated. Just following the steps to perform the operation creates a program template automatically.

Just following the steps to perform the operation creates a program automatically

Supported applications

Pick & place

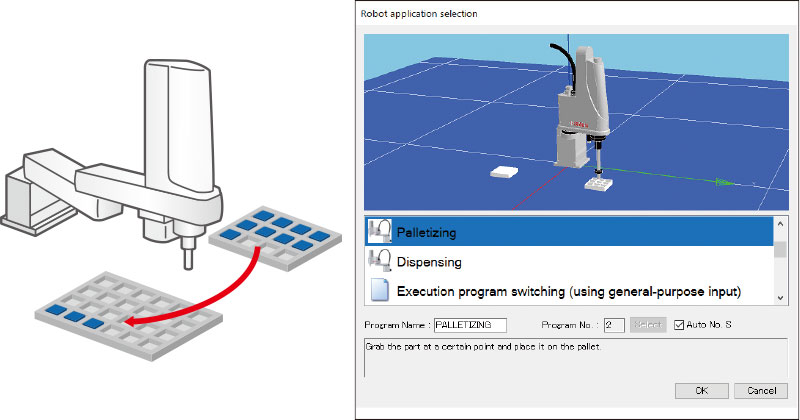

Palletizing

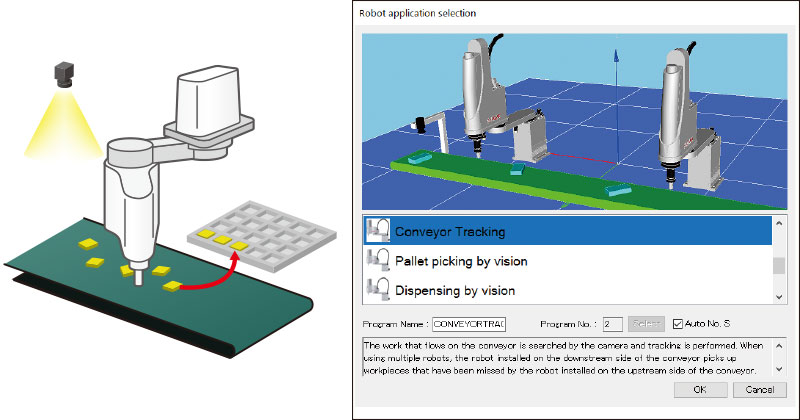

Conveyor tracking

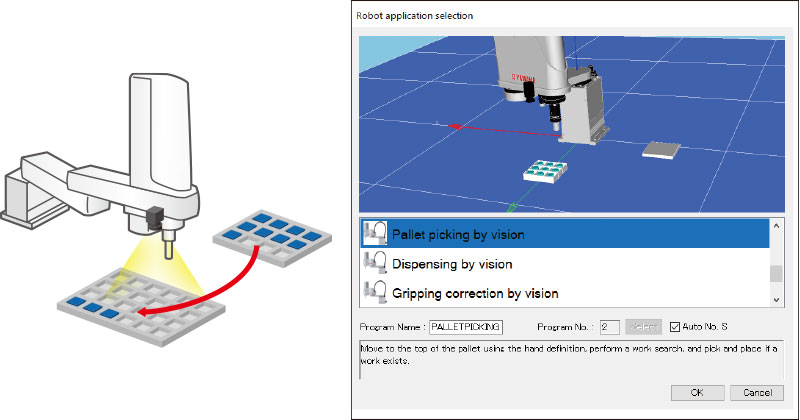

Pallet picking using vision

Parts orientation adjustment on the fly with vision

Switching execution program

Dispensing work

Execution program switching

Dispensing with vision

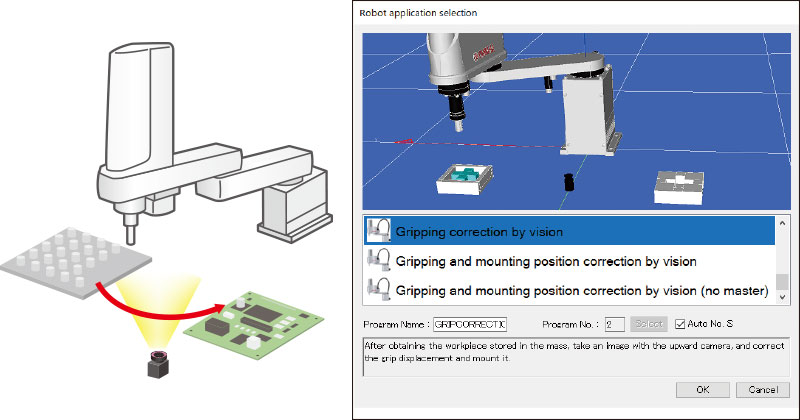

Gripping deviation correction using vision

Parts orientation adjustment on the fly with vision (without master)

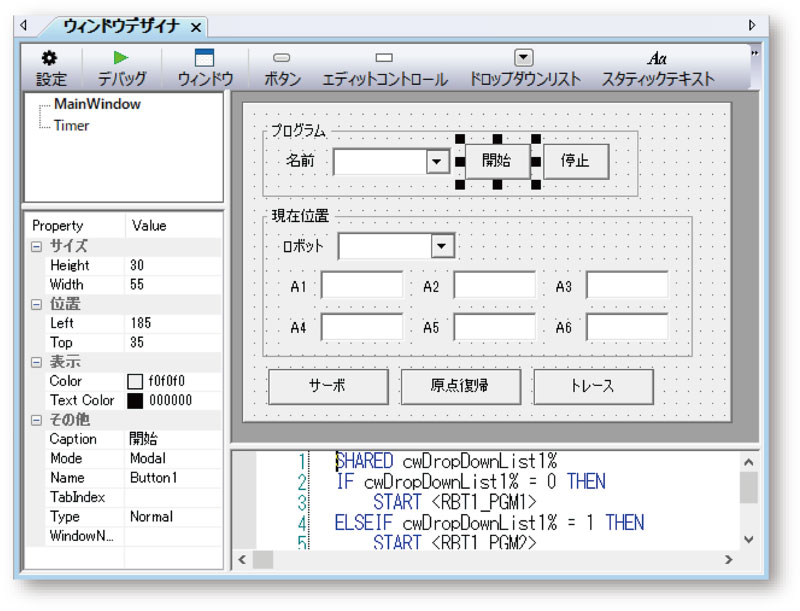

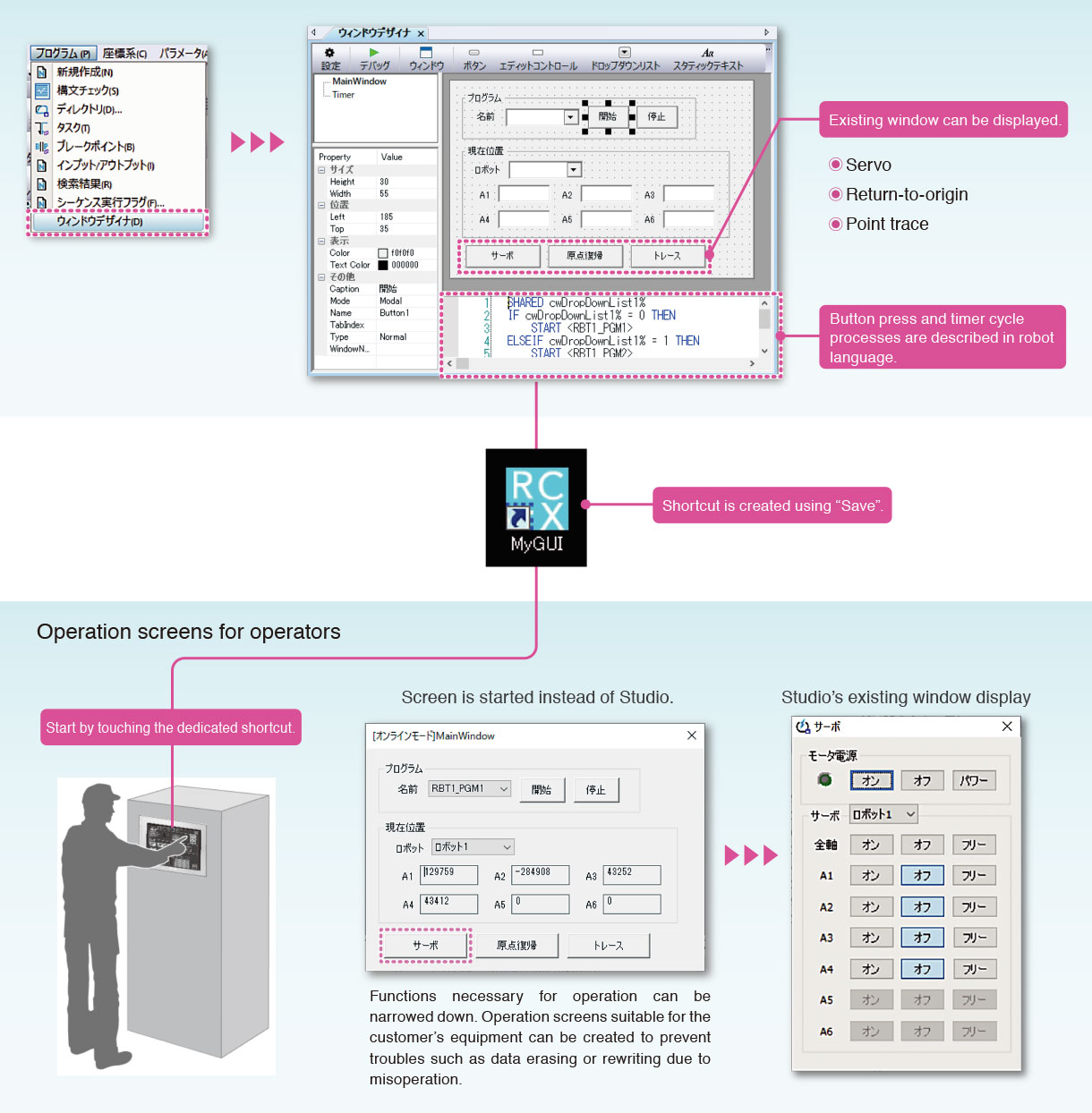

Custom window creation NEW

Operation screens suitable for the customer’s equipment can be created.

GUIs for operators that are displayed on the panel computer can be created.

Creating customized display on PC for operators

Other existing functions

All useful features from RCX-Studio Pro are succeeded to help supporting from startup to maintenance.

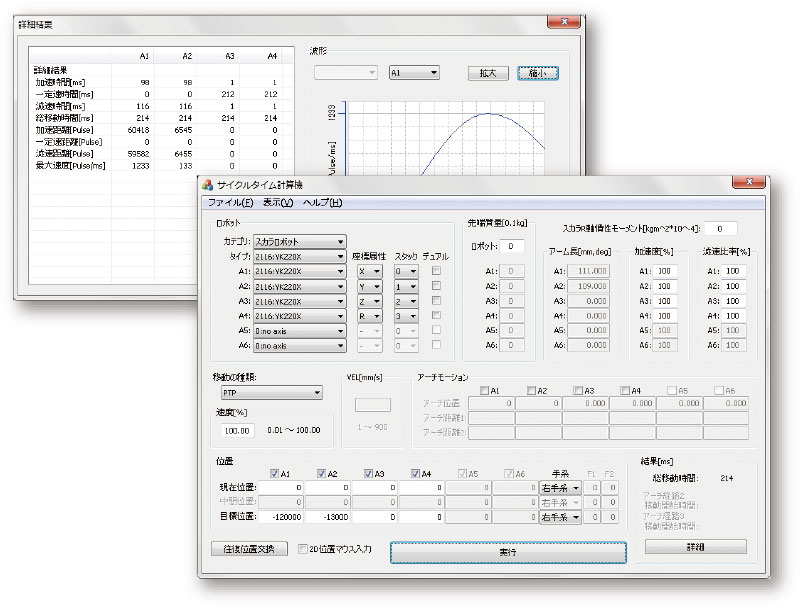

Cycle time calculator

Real time trace

Data comparison

Functions succeeded from “RCX-Studio Pro”

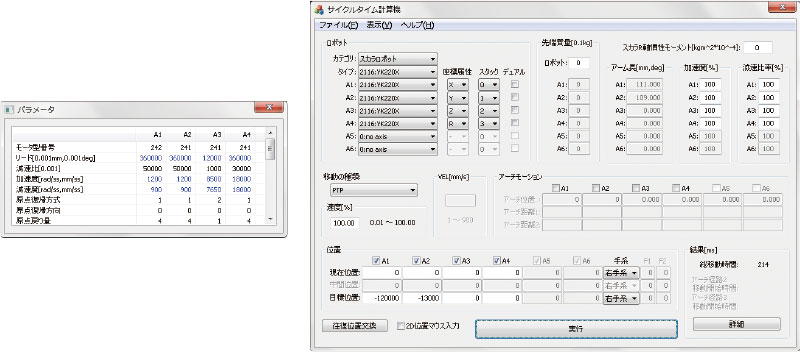

01 Cycle time calculation

Cycle time between two points is calculated simply only with two steps.

By entering a robot model and position data, it will calculate the cycle time.

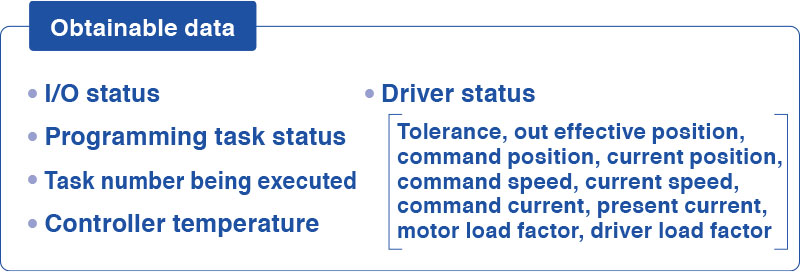

02 Real time trace

Internal information on the controller is output continuously.

Robot status can be checked in real time.

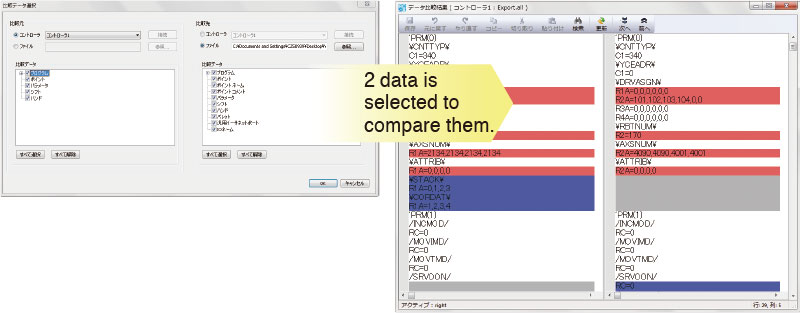

03 Data comparison

Difference between two specified data is displayed visually. Direct comparison with the online data can be performed to greatly reduce the maintenance time.

Various data

User area