Standard type SCARA robots YK-XG

Introduces the medium size standard SCARA robots.

Standard type SCARA robots YK-XG

Completely beltless structure with the tip rotation axis directly connected to the speed reduction gear. This ensures high-accuracy, high-speed, excellent maintenance ability, and amazing tolerable moment of inertia.

Arm length: 500 to 600 mm

Maximum payload: 5 to 20 kg

Feature

01 Internal structure achieving the high-rigidity and high-accuracy

02 Completely beltless structure

A totally beltless structure was achieved by using a ZR axis direct coupling structure. This direct drive structure drastically reduces wasted motion. It also maintains high accuracy over a long period of time. It ensure maintenance-free usage for extended periods with no worries about belt breakage, stretching or deterioration with age (feature applies to all XG series models and the YK180X/YK220X).

03 High speed

The standard cycle time is fast of course but the YAMAHA design also stresses tact time in the actual usage region. A drastic improvement in maximum speed was made by changing the gear ratio and maximum motor rpm. This also resulted in a better tact time during long distance movement.

04 Improved maintenance features

The covers on the YAMAHA SCARA robot YK-XG series can be removed from the front or upwards. The cover is separate from the cable so maintenance tasks are easy.

On ordinary robots replacing the grease on the harmonic gear takes a great deal of time and trouble because the gear must be disassembled and position deviations might occur. On YAMAHA SCARA robots however the harmonic gear is the grease-sealed type so no grease replacement is needed (YK-500XG to YK1000XG).

05 Robot R axis inertia moment capacity

SCARA robot performance is not limited to just standard cycle time. Actual work situations include a diverse range of heavy work pieces as well as work with large offsets. Using a low R axis inertia moment in those cases will help drastically cut the cycle time. All YAMAHA SCARA robots have a speed reducer directly coupled to the tip of the rotating axis. The R axis produces an extremely high allowable inertia moment which delivers high speed operation compared to structures where positioning is usually done by a belt after decelerating.

06 Compact

Changing the cable layout made the overall cable height lower than the unit cover.

Also, utilizing a motor with a small overall length and extrusion material base yielded the smallest dimensions among equipment in the same class.

07 Environmentally rugged resolver provides closed loop control

The position detector is a resolver. The resolver has a simple yet strong structure using not electronic components or elements and so has great features such as being extremely tough in harsh environments as well as a low breakdown rate. The resolver structure has none of the detection problems that occur in other detectors such as optical encoders whose electronic components breakdown or suffer from moisture or oil that sticks to the disk. Moreover, mechanical specifications for both absolute and incremental specifications are common to all controllers so one can switch to either absolute or incremental specifications just by setting a parameter.

Also even if the absolute battery is completely worn down, the SCARA can operate on incremental specifications so in the unlikely event of trouble one can feel secure knowing that there will be no need to stop the production line. The backup circuit has been completely renovated and now has a backup period extending to 1 year.

Note. The resolver has a simple structure not using electronic components at all. It is highly resistant to low and high temperatures, impacts, electrical noise, dust particles, oil, etc. and is used in automobiles, trains, and airplanes.

08 Zone control (automatically sets the maximum acceleration/deceleration) function

On SCARA robots there is a large difference in the load applied to the motor and the speed reducer depending on whether the robot arm is folded or extended. YAMAHA SCARA robots however can automatically set an optimal maximum acceleration and deceleration using the arm status when starting operation and the arm status when ending operation. This capability means that just entering the initial payload will prevent the robot from exceeding tolerance values for motor peak torque and speed reducer allowable peak torque. So full power can be extracted from the motor whenever needed and a high level of acceleration/deceleration maintained.

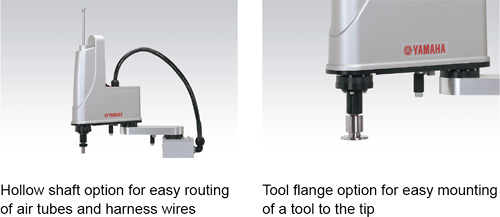

09 Hollow shaft and tool flange options are selectable

Useful options include a hollow shaft for easy wiring to the tip tool and a tool flange for tool clamping.

10 History of 30 years

The first YAMAHA robots were SCARA robots. Since the first SCARA robot called “CAME” was produced in 1979, some 30 years of SCARA robot innovations have continually appeared. These SCARA robots have undergone countless modifications in an everchanging marketplace and amassed a hefty record of successful products making them an essential part of the YAMAHA robot lineup.

User area